WAVECORE® – LIGHTWEIGHT PLASTIC HONEYCOMB

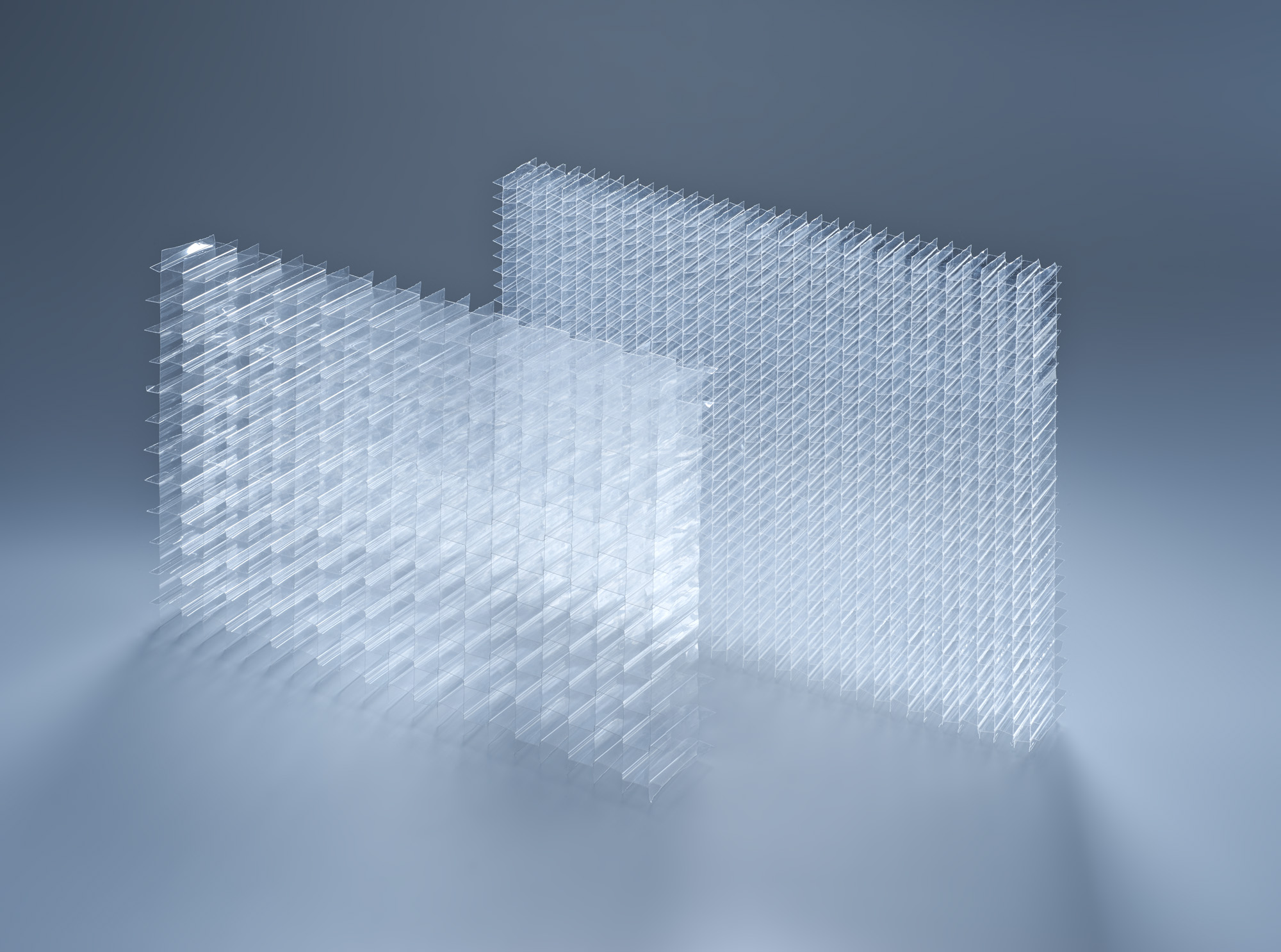

Plastic honeycombs made from PET plastic films in a patented production process.

WaveCore has a uniform diamond-shaped cell structure and is very light. In relation to its low weight, the honeycomb has very high absorption capacity for pressure and shear force. Depending on the type of honeycomb, a compressive strength of up to 0.6 MPa (equivalent to 60 tons of weight per 1 m²) can be absorbed. Honeycomb hole diameters above 9 mm result in lighter honeycombs below 40 kg/m³ and can be mass produced, providing additional cost reductions. Our standard hole widths are 9 and 18 mm respectively.

Features

• Translucent, transparent

• Lightweight with high compressive strength

• Excellent bonding ability with standard adhesives

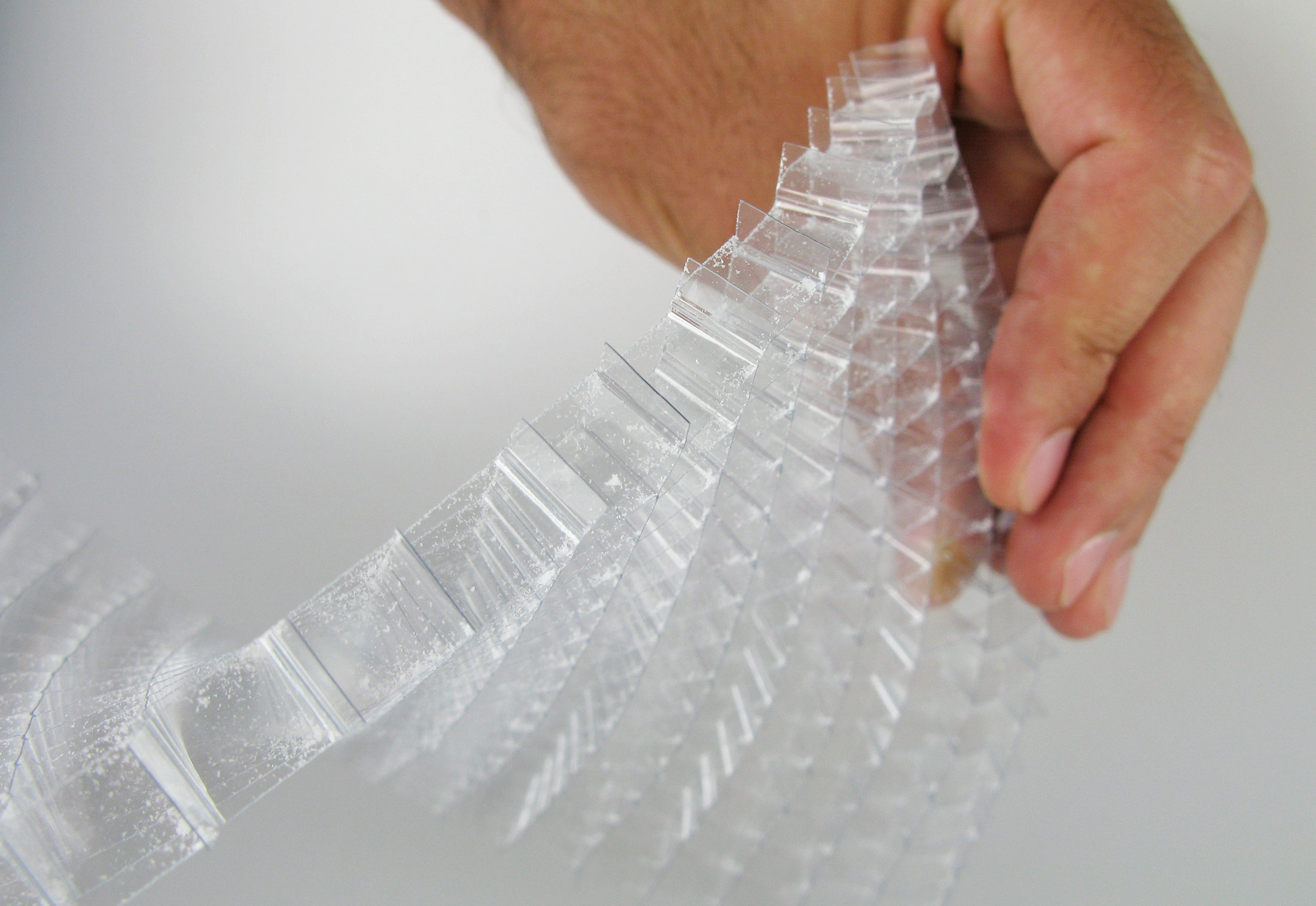

• Thickness ranges from 5mm to 160mm

• Temperature application range from -15°C to +70°C

• B1 fire protection (DIN 4102)

• Easy workmanship/processing

AREAS OF APPLICATION

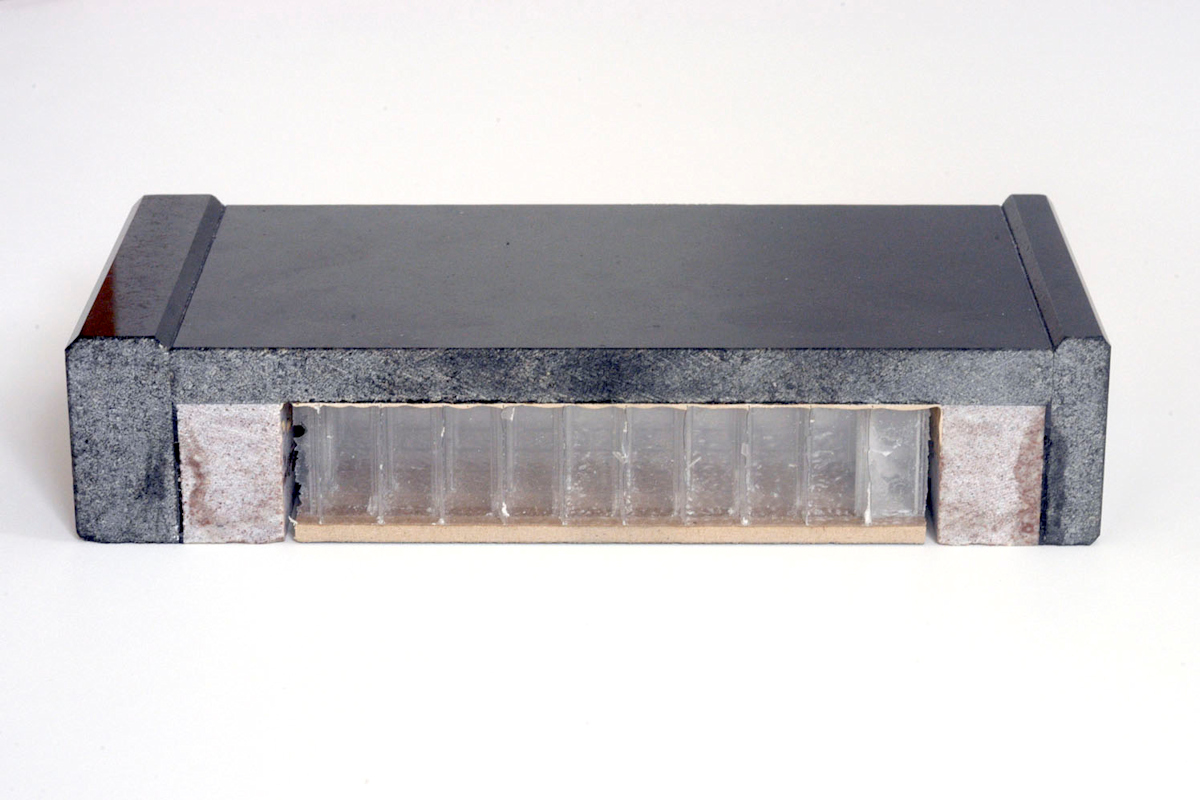

• Core material for lightweight panels / composite panels

• Core material for wet cells / damp rooms

• Laminar flow rectification

PATENTED HONEYCOMB TECHNOLOGY FOR VARYING APPLICATIONS

WaveCore plastic honeycombs are useful when the rigidity of a component needs to be increased or when there is a high moisture load. A practical example is the reinforcement of a kitchen countertop. WaveCore PET bonded to an MDF (medium density fiberboard) support layer stabilizes the kitchen countertop. This increases rigidity and reduces risk of breakage. The honeycomb is impervious to moisture that can occur around a sink. The honeycomb can be glued directly under the work surface. In this case, the work surface forms the second top layer of the composite panel.

Another application of WaveCore is in air-flow straighteners. Turbulent air flows can be converted into laminar, directional flows with the help of honeycomb structures. They are therefore an important design element for air outlets in ventilation ducts. They can also be used for wind tunnels, filters and in air conditioning technology.